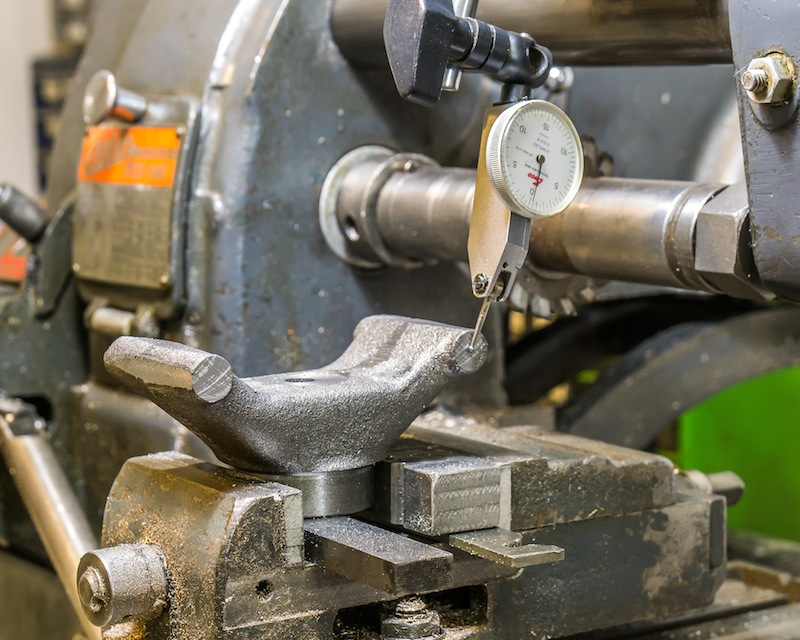

This casting looks like a real bugger to machine, so I might as well do it now and get it out of the way. This is the part of the lead truck attached to the locomotive frame. The photos tell the story of the steps I used to machine this part.

This part was a bugger! I spent approximately twelve (12) hours machining it. Castings are always a challenge to hold and the many interrupted cuts require slow machining. I do not own a vertical milling machine. The horizontal mill works well and the dials are accurate. If you have any questions, please leave them in the comments below.

Hello Tim,

Very nice work! I enjoy your posting of the methods and setups you use. I am very proud that you are sharing your build with the world. Mike and I hope to do the same with the Berk.

As I mentioned at the meeting, after the completion of the pavilion, when we develop a plan for the new shop, it would be nice to have a video library of your build and others who provide photo documentation of their project, so we as a club can use it as a teaching aid. It would, I think break the fear for some to jump into using the machine tools we have out there. Even a small project to get them started. Even if it is only machining a cast iron wheel. I look forward to your next post. See you at the makers fair. Dave W.

LikeLike

Tim I added 2x 1/16 dia oil holes centered above the shafts (if they go all the way through) to help the swing arms move easier.

LikeLike